Industrial Bearings Maintenance Tips: Extending the Life of Your Bearings

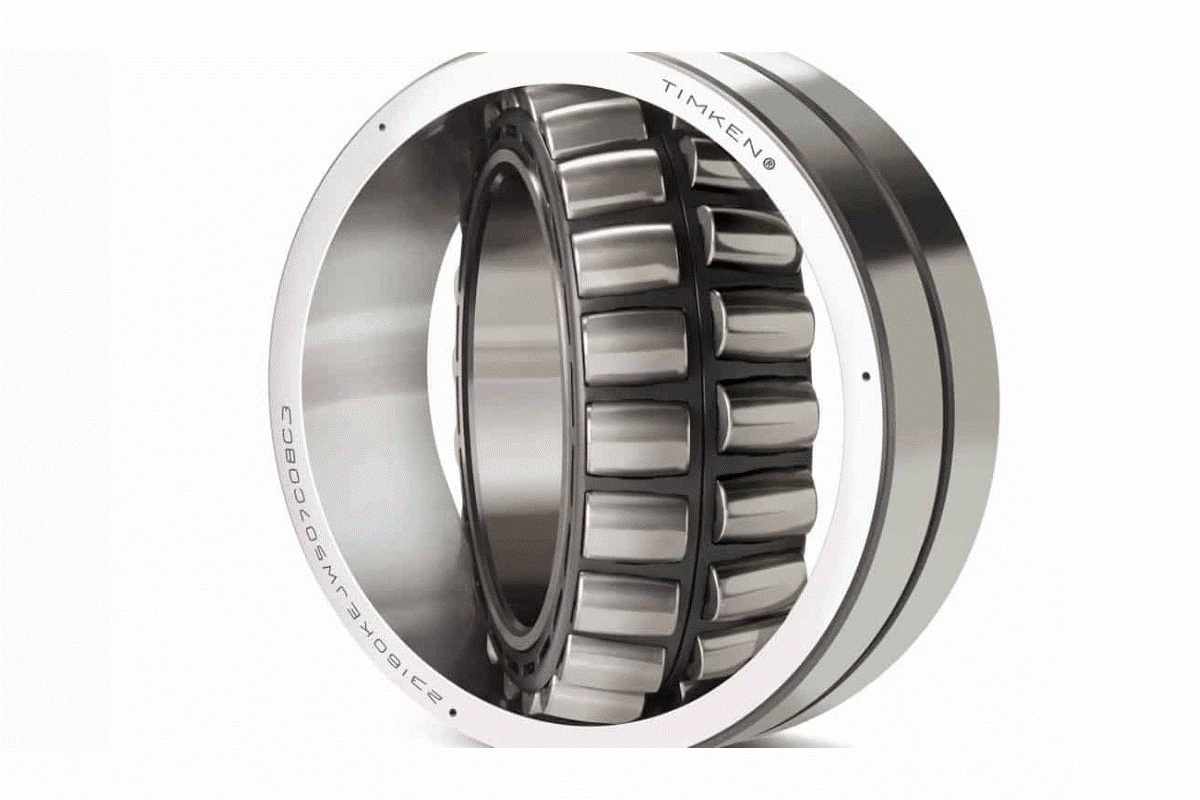

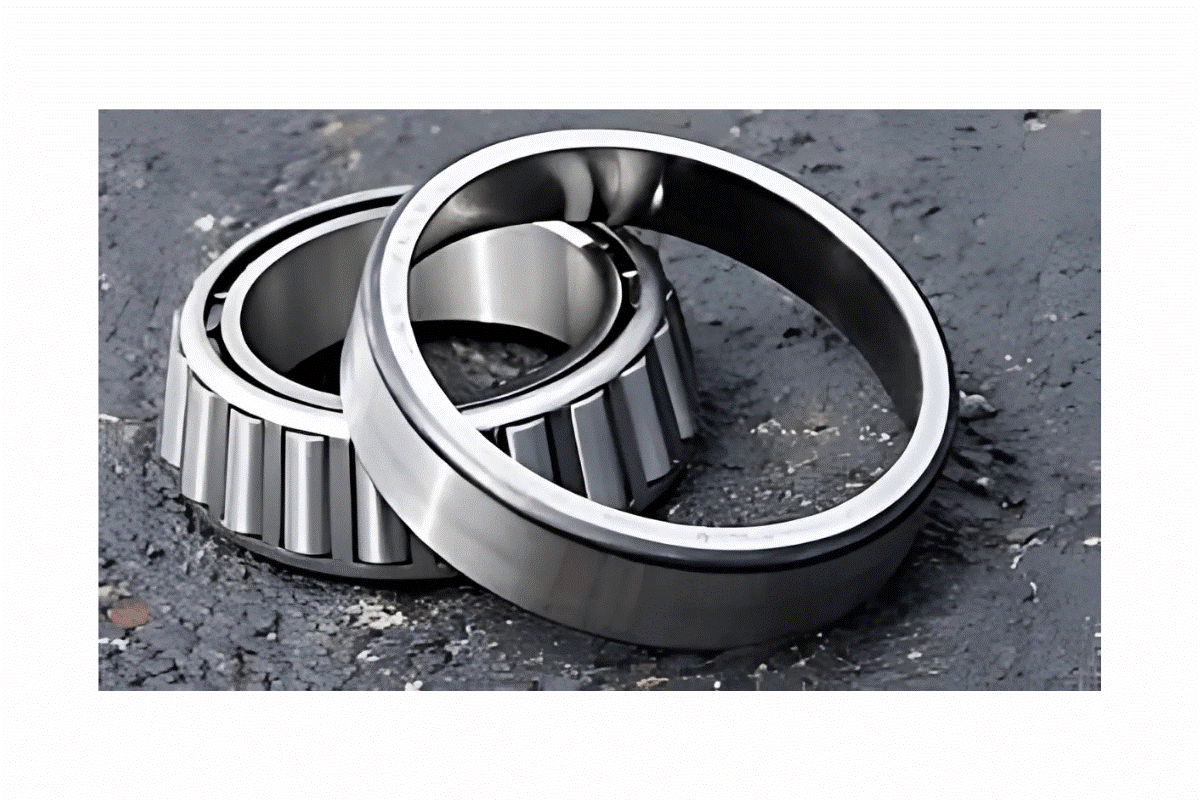

When a machine stops working, the cost is more than just repair—it’s also lost time, missed orders, and damaged trust. At the heart of most mechanical failures? Bearings. These small but powerful components support rotating parts and keep everything running smoothly. But like any other part, they need care. Without proper maintenance, even the best bearings can wear out early. That’s where smart upkeep makes a real difference.

In factories, warehouses, or production lines, one overlooked step in bearing care can slow down operations. To avoid this, let’s look at proven maintenance tips that Industrial Equipment Supplier professionals recommend to keep bearings in top shape. Whether you manage a large facility or handle machinery on-site, these tips will help you a lot.

1. Start With Clean Hands and Clean Tools

One of the most basic, yet most ignored, rules of bearing care is cleanliness. Bearings are precision-made parts. A tiny grain of dirt can act like sandpaper inside the raceway, causing early failure. Always clean your hands before handling bearings. Use lint-free cloths and make sure tools are not greasy or dusty.

Dust from grinding or welding work can also settle in open bearings. Seal off nearby work areas if such tasks are ongoing. Many experts at top Industrial Equipment Supplier companies stress this point again and again—clean surroundings lead to long-lasting equipment.

2. Avoid Over-Lubrication or Under-Lubrication

Lubrication is essential, but more isn’t always better. Excess grease builds heat, which can degrade the lubricant and damage the bearing. On the other hand, too little grease means more friction and faster wear.

The right amount depends on the speed, load, and type of bearing. For example, high-speed bearings may need smaller amounts more often. Use the manufacturer’s guidelines as your base, then track performance. Many teams working with an Industrial Equipment Supplier prefer to automate lubrication using single-point lubricators.

3. Check for Signs of Misalignment

When a shaft or housing is even slightly off-center, the stress on the bearing rises. This causes uneven wear, high noise, and short life. The common causes of misalignment include poor installation, thermal expansion, or worn-out mounting surfaces.

To check for misalignment, look for signs like vibration, heat, or irregular noise. Precision tools like dial indicators or laser alignment kits can help spot issues early.

Your Industrial Equipment Supplier can help you source quality alignment tools or even offer on-site services. Proper alignment protects not only the bearing but also the shaft, seals, and surrounding components.

4. Avoid Overloading the System

Bearings are designed to carry certain loads. When machines run beyond their intended limits, the pressure can crush the rolling elements inside. Overloading causes metal-to-metal contact and leads to cracks, fatigue, and rapid failure.

Make sure your machines are operating within the rated load. Choosing the right bearing also matters. A trusted Industrial Equipment Supplier will help you match the load with the right product, avoiding size or type mismatches that can lead to overload.

5. Schedule Routine Inspections and Keep Records

Maintenance isn’t a one-time job. Bearings should be inspected regularly—at least every three months. Look for signs of rust, discoloration, leaks, or noise. Use tools like vibration meters, thermal cameras, and stethoscopes to detect problems early. The most reliable Industrial Equipment Supplier teams use digital tools to track maintenance.

Conclusion

Bearings may look small, but they carry a big responsibility. By keeping them clean, well-lubricated, properly aligned, and regularly inspected, you can extend their life and prevent unexpected downtime. It’s not just about saving money—it’s about keeping your machines running when it matters most.

For companies in Dubai looking for top-quality products and support, Smart Elemech is a trusted Industrial Equipment Supplier known for expertise and fast service.

Visit Smart Elemech today and let us help you keep your machinery running strong. Get in touch with our team at +971 67043799.